The sterile tubing welder market, valued at USD 2.34 billion in 2023, is poised for substantial growth from 2024 to 2032, with an anticipated CAGR of 4.8%. By 2032, it is expected to reach a market value of USD 4.10 billion. This remarkable expansion can be attributed to several driving factors, including the increasing demand for personalized medicines, the rising prevalence of blood disorders, and the rapid expansion of healthcare infrastructure worldwide. In this extensive article, we will explore the market outlook, provide an overview of the industry, examine market dynamics, delve into segmentation, discuss recent developments, analyze component insights, assess end-user perspectives, investigate regional trends, profile key players, scrutinize emerging market trends, stay updated on industry news, and gain insights into application areas.

Market Outlook

The sterile tubing welder market has been on an upward trajectory for the past decade, and this growth is expected to continue from 2024 to 2032. The market’s prospects are influenced by various factors, encompassing the surging demand for personalized medicines, the increasing incidence of blood disorders, and the ongoing expansion of healthcare facilities across different nations.

Rising Demand for Personalized Medicines

A pivotal driver of the sterile tubing welder market is the escalating demand for personalized medicines. In the realm of medical science and technology, there is a noticeable shift towards treatments tailored to individual patients. Achieving this personalized approach requires precise manufacturing and assembly of medical devices and equipment, including sterile tubing welders, which play a vital role in ensuring the integrity of these medical components.

Increasing Prevalence of Blood Disorders

Another substantial factor propelling the market’s growth is the growing prevalence of blood disorders. Conditions such as hemophilia, leukemia, and anemia necessitate frequent blood transfusions and medical interventions. The safe and sterile transfer of blood components is crucial in these cases, making sterile tubing welders indispensable for maintaining the integrity of blood transfusion equipment and consequently driving market growth.

Rapid Expansion of Healthcare Infrastructure

The global healthcare infrastructure is undergoing rapid modernization and expansion. Nations, both developed and developing, are making significant investments in healthcare facilities, including hospitals, clinics, and diagnostic centers. As these healthcare establishments increase in number and sophistication, the demand for sterile tubing welders for medical equipment manufacturing and maintenance grows correspondingly.

Report Overview

To gain an in-depth understanding of the sterile tubing welder market from 2024 to 2032, it is essential to explore various aspects, including market size, dynamics, segmentation, recent developments, component insights, end-user perspectives, regional trends, key players, emerging market trends, industry updates, and application insights.

Market Size

The sterile tubing welder market, valued at USD 2.34 billion in 2023, is projected to achieve a CAGR of 4.8% during the forecast period, reaching USD 4.10 billion by 2032. This impressive growth trajectory underscores the increasing significance of sterile tubing welders across various medical applications.

Market Dynamics

The dynamics of the sterile tubing welder market are influenced by a multitude of factors, including technological advancements, regulatory changes, economic conditions, and evolving healthcare practices. Staying agile and adaptable to changing dynamics is imperative for manufacturers in this industry to seize growth opportunities effectively.

Segmentation

The sterile tubing welder market can be segmented based on several parameters, including component type, end-user, and geographical location. These segments enable a more targeted analysis of the market, aiding businesses in tailoring their strategies accordingly.

Recent Developments

Keeping abreast of recent developments in the sterile tubing welder market is vital for stakeholders. Innovations in welding technology, materials, and sterilization methods can significantly impact market dynamics and competitiveness.

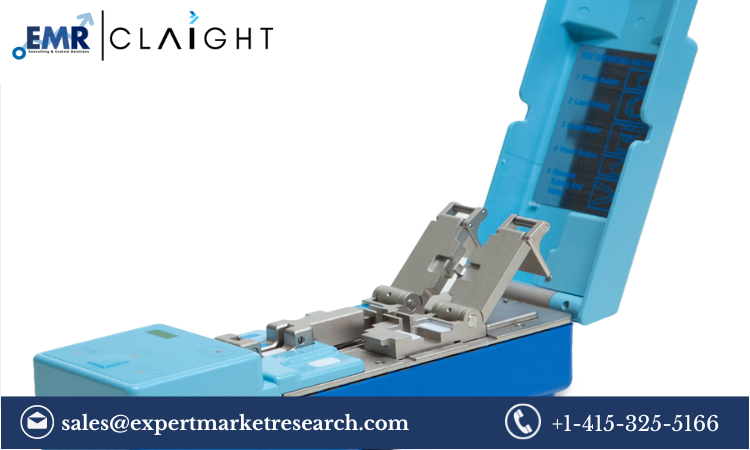

Component Insights

Sterile tubing welders comprise various components that collectively ensure the sterility and functionality of medical tubing. These components are instrumental in maintaining the integrity of medical equipment.

Key Components

- Electrodes: Electrodes are pivotal components in sterile tubing welders, generating the necessary heat for fusing tubing materials together. Advances in electrode design and materials have led to more precise and efficient welding processes.

- Control Systems: Control systems in sterile tubing welders allow operators to regulate welding parameters, including temperature, pressure, and duration. User-friendly interfaces and automation features are increasingly common, enhancing overall welding process efficiency.

- Sterilization Units: Sterilization units are essential for ensuring that the welded tubing remains sterile and free from contaminants. Innovations in sterilization methods, such as UV sterilization and gas sterilization, contribute to the reliability of sterile tubing welders.

- Monitoring and Quality Control Systems: Quality control is paramount in medical equipment manufacturing. Monitoring and quality control systems in sterile tubing welders help detect and rectify defects, ensuring the safety and reliability of medical tubing.

End-user Insights

Understanding the diverse end-user base of sterile tubing welders is crucial for market players to effectively tailor their offerings.

Medical Device Manufacturers

Medical device manufacturers constitute a primary end-user group for sterile tubing welders. They rely on these machines to assemble various medical components, including catheters, IV tubing, and blood bags. The precision and sterility offered by tubing welders are critical for ensuring the safety and efficacy of these medical devices.

Hospitals and Clinics

Hospitals and clinics also utilize sterile tubing welders for the maintenance and repair of medical equipment. Ensuring the integrity of equipment used in patient care is a top priority, and sterile tubing welders play a pivotal role in achieving this.

Research and Development Facilities

Research and development facilities rely on sterile tubing welders for prototyping and testing new medical devices. These facilities depend on precise welding processes to develop innovative healthcare solutions.

Regional Insights

The sterile tubing welder market exhibits regional variations in demand and growth patterns. Understanding these regional trends is essential for devising effective market expansion strategies.

North America

North America emerges as a prominent market for sterile tubing welders, driven by its well-established healthcare sector, substantial R&D investments, and a strong emphasis on quality and safety. The United States, in particular, plays a significant role in driving market growth.

Europe

Europe represents another key region in the sterile tubing welder market, characterized by stringent regulatory standards and a robust healthcare infrastructure. Countries such as Germany and the United Kingdom are at the forefront of demand.

Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in healthcare infrastructure, positioning it as an emerging market for sterile tubing welders. China and India, with their large populations and increasing healthcare investments, are pivotal players in this region.

Latin America and the Middle East

Latin America and the Middle East are also witnessing steady growth in healthcare facilities, contributing to the demand for sterile tubing welders. These regions present untapped opportunities for market expansion.

Key Players

Several key players dominate the sterile tubing welder market, each contributing to the industry’s growth through innovation and product development. Prominent companies in this market include:

- Dukane Corporation

- Genesis Plastics Welding

- Seiler Plastics Corporation

- Eastman Machine Company

- Branson Ultrasonics Corporation

- Biomerics

These companies are continually striving to enhance their product offerings, improve manufacturing processes, and expand their global presence.

Market Trends

Understanding market trends is essential for businesses to maintain their competitiveness. Here are some emerging trends in the sterile tubing welder market:

1. Automation and Robotics

Automation and robotics are increasingly integrated into sterile tubing welding processes to enhance precision and efficiency. This trend reduces the risk of human error and elevates the overall quality of welded medical components.

2. Sustainable Materials

Growing environmental concerns are driving the adoption of sustainable materials in medical tubing. Manufacturers are exploring eco-friendly alternatives that meet sterilization and safety standards.

3. Miniaturization

Advancements in microfluidics and miniaturization technologies are leading to the development of smaller, more portable sterile tubing welders. These compact machines are suitable for point-of-care applications and field use.

4. Industry 4.0 Integration

Integration with Industry 4.0 principles is transforming the sterile tubing welder market. Real-time monitoring, data analytics, and predictive maintenance are becoming standard features, ensuring seamless operations and reducing downtime.

5. Regulatory Compliance

Stringent regulatory standards continue to shape the market. Manufacturers are investing in research and development to meet evolving regulatory requirements and maintain compliance.

Industry News

Staying informed about the latest industry news is crucial for gaining a competitive edge. Here are some recent developments in the sterile tubing welder market:

- In 2024, Dukane Corporation introduced an advanced sterile tubing welder equipped with robotics for precise and efficient welding processes.

- Biomerics announced a strategic partnership in 2025 with a leading medical device manufacturer to develop customized sterile tubing solutions for next-generation medical devices.

- The FDA updated its guidelines in 2025, emphasizing the importance of sterile tubing welder validation and quality control in medical device manufacturing.

Application Insights

Sterile tubing welders find applications in a diverse range of medical devices and equipment. Understanding these applications provides insights into the market’s depth and significance.

IV Tubing

Sterile tubing welders play a crucial role in the assembly of IV tubing sets, ensuring airtight connections and preventing contamination during fluid administration.

Catheters

Catheters used in various medical procedures rely on sterile tubing welders to maintain the integrity of their components, promoting patient safety.

Blood Bags

The safe and sterile transfer of blood and blood components is essential. Sterile tubing welders are instrumental in the production of blood bags, contributing to the healthcare industry’s ability to meet the demand for safe blood transfusions.

Medical Fluid Transfer Systems

Sterile tubing welders are integral to medical fluid transfer systems, such as those used in dialysis and chemotherapy, where precise and sterile connections are paramount.

Bioprocessing Equipment

Bioprocessing equipment used in pharmaceutical and biotechnology applications often requires sterile tubing welders to maintain sterile conditions throughout the manufacturing process.

FAQs

Q1: What is the projected growth rate of the sterile tubing welder market from 2024 to 2032?

A1: The sterile tubing welder market is expected to achieve a CAGR of 4.8% during the forecast period, reaching a market value of USD 4.10 billion by 2032.

Q2: What factors are driving the growth of the sterile tubing welder market?

A2: The growth of the market is primarily driven by the increasing demand for personalized medicines, the rising prevalence of blood disorders, and the rapid expansion of healthcare infrastructure across nations.

Q3: Who are the key players in the sterile tubing welder market?

A3: Key players in the market include Dukane Corporation, Genesis Plastics Welding, Seiler Plastics Corporation, Eastman Machine Company, Branson Ultrasonics Corporation, and Biomerics, among others.

Q4: What are the emerging trends in the sterile tubing welder market?

A4: Emerging trends in the market include the integration of automation and robotics, the adoption of sustainable materials, miniaturization, Industry 4.0 integration, and a heightened focus on regulatory compliance.

Q5: How are sterile tubing welders used in the healthcare industry?

A5: Sterile tubing welders are used for the assembly and maintenance of various medical devices, including IV tubing, catheters, blood bags, medical fluid transfer systems, and bioprocessing equipment.

Media Contact:

Company Name: Claight Corporation

Contact Person: Joe Goldberg, Business Consultant

Email: sales@expertmarketresearch.com

Toll-Free Number: US +1-415-325-5166 | UK +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA